- Home

- Product Detail - Small forged HF acid check valves

Product Detail

-(1).png)

-

Bimetallic steam traps

- Type MFA & MFAS compressed air drain traps

- Type MFT & MFTS float bimetallic steam traps

- Type N forged HP/HT steam traps

- Type Q250 hermetically-sealed steam traps

- Type SPF & SP high capacity piston-operated steam traps

- Type SSF steam traps

- Type TS, TSF & SF forged steam traps

- Piping King package units

- Thermodynamic steam traps

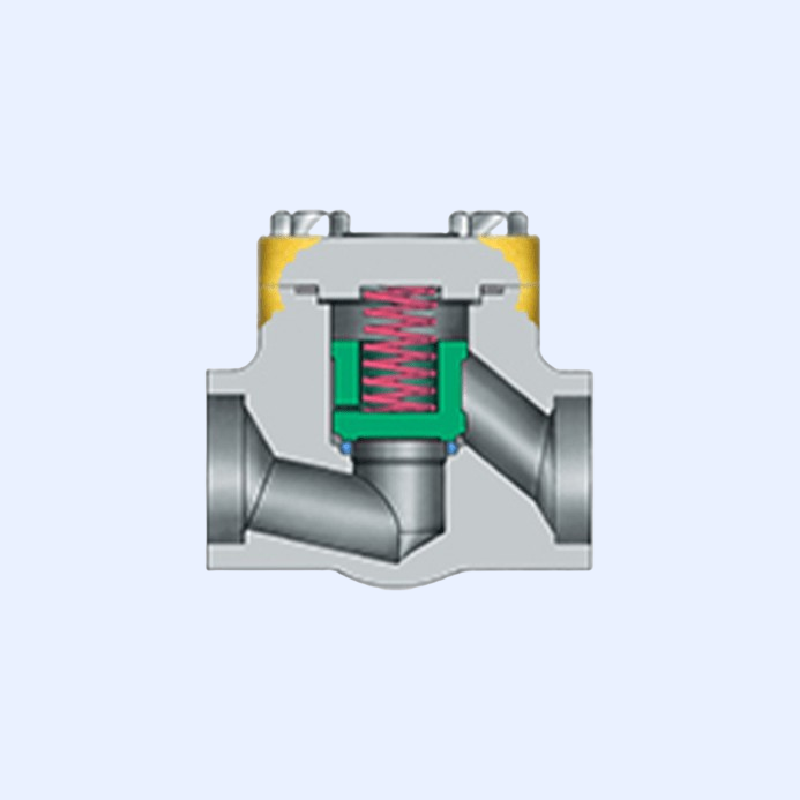

Small forged HF acid check valves

Description

Flowcen’s Forged HF Acid Check Valves are designed for hydrofluoric acid (HF) service and other highly corrosive applications, ensuring unidirectional flow and preventing backflow in critical industrial processes. Engineered with high-performance alloys, these valves offer superior corrosion resistance, high-pressure capability, and long service life, making them ideal for refineries, petrochemical plants, and chemical processing industries. With a forged body construction, these check valves provide enhanced strength, leak-tight sealing, and resistance to extreme operating conditions, ensuring safe and efficient performance in demanding environments.

Product Details

-

Size Range: ¼" to 2" (DN6 to DN50)

-

Pressure Class: ANSI 150, 300, 600, 900, 1500, 2500 / PN10 to PN420

-

Body Material: Cast steel,Monel, Alloy 400, Hastelloy, Inconel, Stainless Steel

-

Trim Material: Corrosion-Resistant High-Alloy Materials

-

Seat Type: Metal-to-Metal Seating

-

Temperature Range: -50°C to 500°C

-

End Connections: Threaded, Socket Weld, Butt-Weld, Flanged (RF, RTJ)

Features and Benefits

-

Compact & High-Performance Design – Ideal for small piping systems in critical applications.

-

Exceptional Corrosion Resistance – Suitable for hydrofluoric acid and aggressive chemicals.

-

Reliable Backflow Prevention – Ensures unidirectional flow for system protection.

-

High-Pressure & Temperature Tolerance – Designed for demanding industrial environments.

-

Forged Body Construction – Provides superior strength and durability.

-

Low Maintenance & Extended Service Life – Minimizes downtime and operational costs.

-

Compliance with Industry Standards – Designed for refineries, petrochemicals, and chemical processing plants.